On June 30, 2016, ASIPP successfully delivered the large superconducting feeder system to General Atomics (GA). The system will be used for the ITER center solenoid coil test in the U.S National Laboratory for Fusion.

This project is completely self-developed by ASIPP, with the support of JUNENG, KEYE and KEJU CRYOGENICS during the stage of manufacture, assembling, testing and transportation, etc. ASIPP owns the complete intellectual property rights in design, manufacture, assembling and test of the system.

This is a successful case of high-tech outputting from ASIPP to U.S, which will strengthen further cooperation between China and U.S in the field of Fusion Engineering. Dr James Van Dam, Director of Research Division, Fusion Energy Sciences, Office of Science, U.S. Department of Energy (DOE), highly affirmed the significance of this project. Meanwhile, the completion of this project is also a successful early-stage practice for ITER superconducting feeder system, providing technology and experience to guarantee smooth implementation of the ITER feeder procurement package directly.

The superconducting feeder system consists of a pair of HTSCL (high-temperature superconducting current leads), coil terminal box, cryostat feeder through, busbar and cryogenic pipes. The system will not only provide large current, supercritical helium, measurement and control signal for ITER center solenoid coil test, but also release the coil energy and protect the system in the quench of coil system.

This system is 10 meters long, 4.5 meters high and 25 tons weight. The whole project involves the disciplines of mechanical, electromagnetic, cryogenic, vacuum, superconductivity, etc. Through three years' tense effort, the R&D team solves many key technologies: the joint resistance is less than 0.6 n Ω, the quench time is more than 10 minutes, the 15 kV high voltage insulation on the complicated structure on normal and Paschen condition. These key technologies are even more superior to the international level.

At the end of 2015, the study team completed 55 kA current steady running and Loss of Flow Accident test (LOFA). All the parameters meet the design requirements: the lowest temperature of system is less than 5 K, the temperature of thermal shield is less than 90 K, the vacuum is lower than 1e-4 pa, the quench time is more than 10 minutes, the superconducting joint resistance is less than 0.6 n Ω,the heat load to 5 K is about 70W. During the first half of 2016, the challenge on insulation was overcome, including the insulation wrapping, curing, electric field shielding, voltage measurement, high voltage test and Paschen test of the complicated system. As a result, the insulation performance of the large system is better than the design requirements.

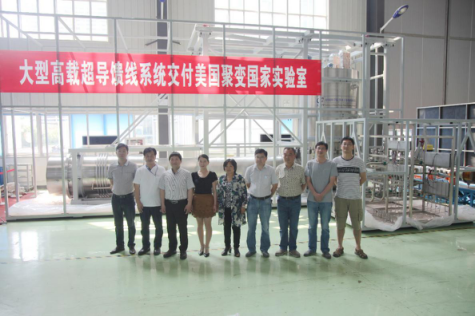

Witnessed by Partners

Dr. James Van Dam Visits the System

Ready for Delivery

Tel: +86-551-65591206

Tel: +86-551-65591206

Fax: +86-551-65591270

Fax: +86-551-65591270

Emai: zhous@hfcas.ac.cn

Emai: zhous@hfcas.ac.cn

350 Shushanhu Road

350 Shushanhu Road