20MW m-2 was reached! A research team led by professor YAO Damao from the Institute of Plasma Physics, Hefei Institutes of Physical Science (HFIPS) made important progress in the development of ultra-high thermal load tungsten divertor components.

As important components of the nuclear fusion device, divertors - designed to handle power exhaust - is one of the key issues for next step fusion reactors.

The team developed a kind of flat-type high heat load tungsten mock-up. It consisted of 2mm thickness pure tungsten bonded to pure copper and brazed to CuCrZr heat sink, with 1mm oxygen-free copper (OFC) as interlayer. Besides, special thermal transfer structure was designed in the heat sink, which significantly improved the heat transfer efficiency. The heat removal capacity of the mock-up was upgraded from the initial 5MW-2 in 2017 to 15MW m-2 in 2018, and then reached 20MW m-2 currently.

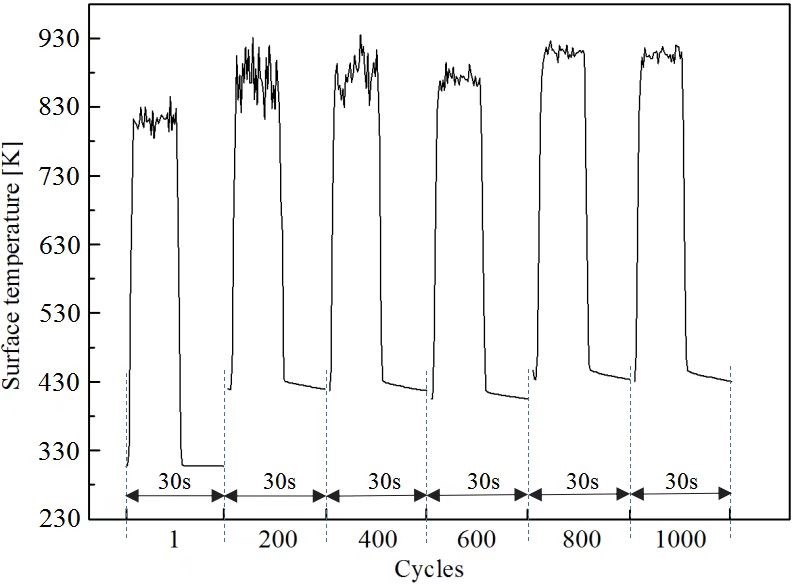

The mock-up withstood successfully 1000 cycles of high heat flux (HHF) test of 20MW m-2 (15 seconds on and 15 seconds off) on the electron beam facility. The tungsten surface temperature was maintained within 930°C less than the recrystallization temperature of pure tungsten (1200°C). After 1000 cycles of HHF tests, there was no obvious degradation of the heat transfer performance (HTP) and damage of the mock-up.

The next step is to apply the technology to the EAST tungsten divertor to demonstrate its reliability and suitability for high-performance long-pulse plasma.

Figure 1a. The sample picture before 1000 cycles heat load of 20MW m-2 (Image by LI Lei)

Figure 1b. The sample picture after 1000 cycles heat load of 20MW m-2 (Image by LI Lei)

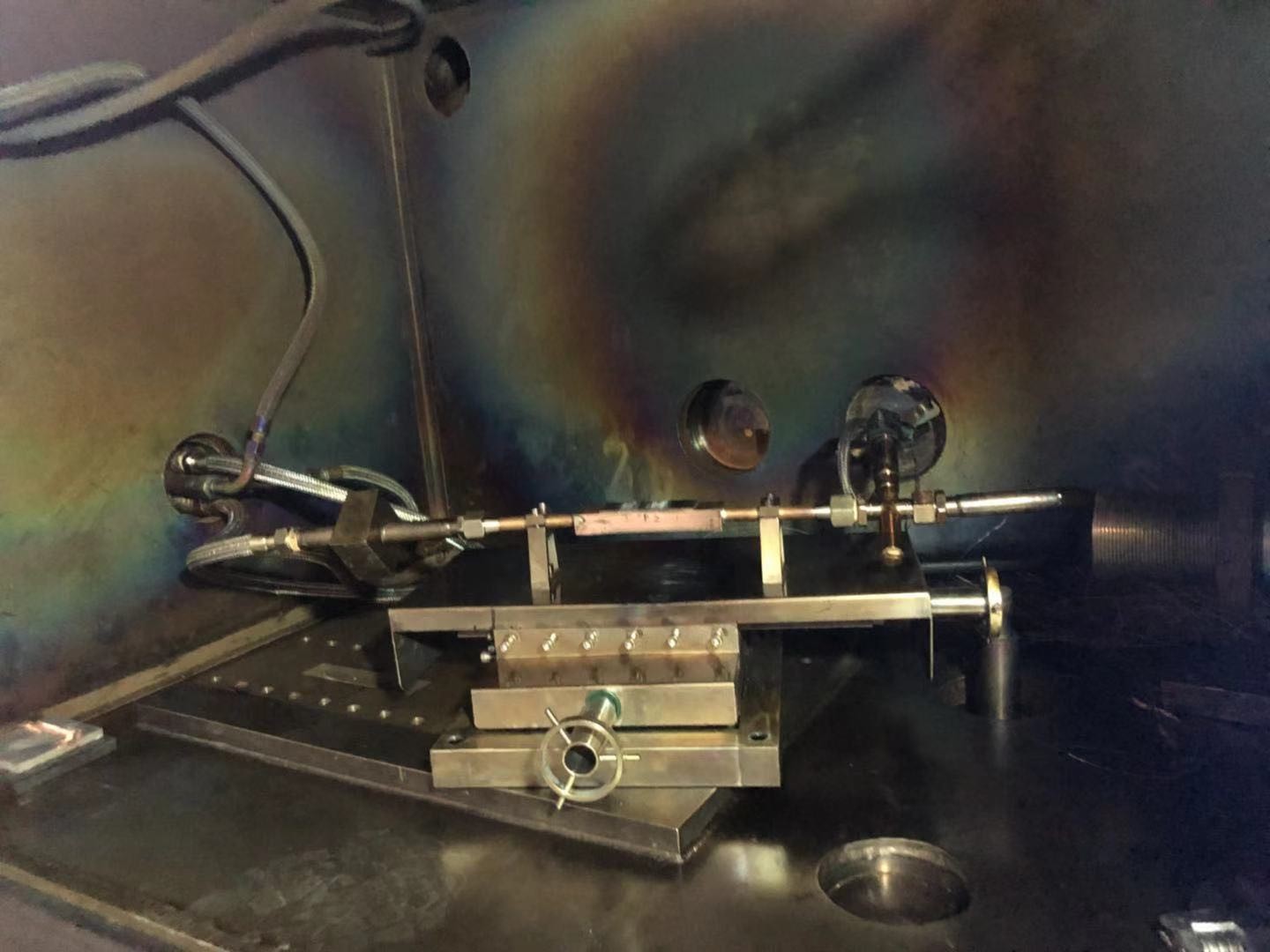

Figure 2. The electron beam testing device (Image by LI Lei)

Figure 3. The tungsten surface temperature measurement value during 1000 cycles heat load of 20MW m-2 (Image by LI Lei)

Contact:

ZHAO Weiwei

Hefei Institutes of Physical Science (http://english.hf.cas.cn/)

Email: annyzhao@ipp.ac.cn

Tel: +86-551-65591206

Tel: +86-551-65591206

Fax: +86-551-65591270

Fax: +86-551-65591270

Emai: zhous@hfcas.ac.cn

Emai: zhous@hfcas.ac.cn

350 Shushanhu Road

350 Shushanhu Road