Recently, Prof. WANG Zhenyang’s research group from Institute of Solid State Physics, Hefei Institutes of Physical Science (HFIPS), Chinese Academy of Sciences (CAS), has made new progress in the large-area preparation of macroscopic thick three-dimensional (3D) porous graphene films.

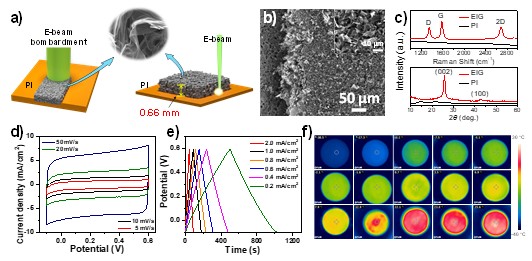

Researchers used high-energy e-beam as the energy source and took the advantages of the high kinetic energy and low reflection characteristics of e-beam to directly induce polyimide precursor into a 3D porous graphene crystal film with a thickness of up to 0.66 mm. Related research results were published in the journal Carbon.

Graphene has been proved to be a new strategic material owing to its numerous exceptional chemical and physical properties. Integrating dimensional (3D) porous graphene network can prevent restacking of graphene sheets and enables easy access and diffusion of ions. However, efficient synthesis of macroscopic thick 3D porous graphene films is still a challenge.

The high instantaneous energy of laser can induce the direct carbonization of the carbon-containing matrix to form high crystalline quality graphene. But the penetration depth of the laser into the carbon-containing matrix is quite low, resulting in insufficient thickness of the prepared graphene film, which limits its application in actual devices. Therefore, exploring a more effective energy source is a key problem that needs to be solved urgently for the industrial application of high-energy beam induced graphene.

In this research, scientists used high-energy e-beam as a new energy source to successfully realize the efficient preparation of macroscopic thick 3D porous graphene crystal films on the polyimide precursor. Compared with lasers, high-energy e-beam possessed lots of advantages including zero reflection, high kinetic energy, injection effect, and simple focus control, making the e-beam to be a possible better energy source than laser, which could quickly induce carbonization of polyimide precursors to produce graphene.

Hydrogen, oxygen and some other components in polyimide can rapidly escape in the form of gas, resulting in abundant 3D pore structure of graphene.

This study exhibits that the thickness of e-beam induced graphene (EIG) film is as high as 0.66 mm, and the synthesis rate is 84 cm2/min, which is significantly larger than laser. Furthermore, EIG has been successfully applied to the field of supercapacitor electrodes, which shows excellent electrochemical storage capacity.

With prominent photothermal performance, EIG can also be applied to the field of solar photothermal anti-icing and deicing. The temperatures can be -40 °C, which is ultra-low.

The above work has been supported by the National Key Research and Development Project, the National Natural Science Foundation of China, and the Anhui Key Research and Development Program.

Article link: E-beam direct synthesis of macroscopic thick 3D porous graphene films

Fig. 1 (a) A schematic diagram of the process of e-beam bombardment to induce graphene on polyimide; (b) SEM image of EIG; (c) Raman spectra (above) and XRD spectra (below) of EIG and polyimide film. (d) The CV curves at different scan rates of EIG electrode; (e) The GCD diagrams at different current densities of EIG electrode; (f) Photothermal performance of EIG materials at -40 °C. (Credit by LI Nian)

ZHAO Weiwei

Hefei Institutes of Physical Science (http://english.hf.cas.cn/)

Email: annyzhao@ipp.ac.cn

Contact:

Tel: +86-551-65591206

Tel: +86-551-65591206

Fax: +86-551-65591270

Fax: +86-551-65591270

Emai: zhous@hfcas.ac.cn

Emai: zhous@hfcas.ac.cn

350 Shushanhu Road

350 Shushanhu Road