Recently, the high-precision optical components processing team from optical engineering center of AIOFM has finished one set Thomson scattering diagnostic system for big view field of EAST boundary whose relative aperture is 1:2. This system will be installed in EAST to collect data for depth test.

In the beginning of July, this system passed the pre-acceptance operated by some experts who thought this system achieves domestic advanced level. The optical tube of this system is one third shorter than other systems. So that the installment of energy collection and test process is simplified and the test room is compressed

Because the surface of high refractive index optical material used in this system is liable to corrode and oxidize, especially the surface atomization, the team optimized the techniques press of machining and coating. Because optical material is soft and has big diameter, surface cleaning before coating is extremely important. This team worked hard to find out a new method to ensure the success of coating.

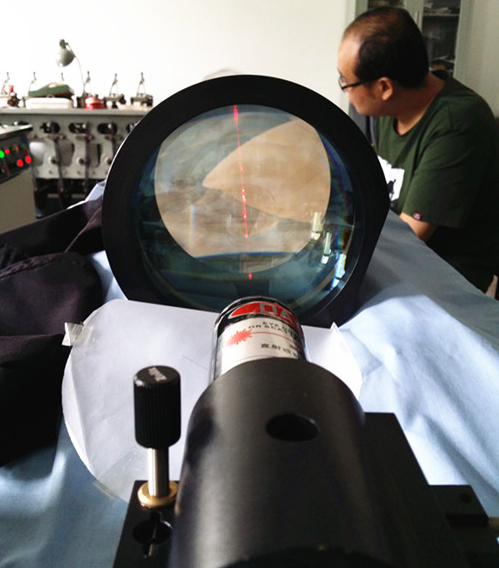

Precision of optical axis and out circle, tolerance of tube and distance between lenses are necessary to make sure that all spherical centers of each lens are on one line. The team measured the vector height of each lens, selected high strength and high stiffness structure material to ensure the optical position of each lens.

It took ten months for optical engineering center to complete this hard and significant work including optical design, material selection, optical processing and coating. It is the first time for this center to design process and install this kind of big optics lens. This success shows the comprehensive strength of AIOFM, which means that AIOFM is capable of processing high precision optics component.