A research team led by Prof. ZHAO Peng from the Institute of Plasma Physics, the Hefei Institutes of Physical Science the Chinese Academy of Sciences, has completed a long-duration test of a single 5 MW plasma torch designed for industrial metallurgical applications. Developed in collaboration with Baowu Equipment Intelligent Technology CO., LTD. and Baowu Heavy Industries CO., LTD, the system has been operating continuously for 172 hours on the off-line experimental platform at Xinjiang Bayi Iron & Steel Co., Ltd.

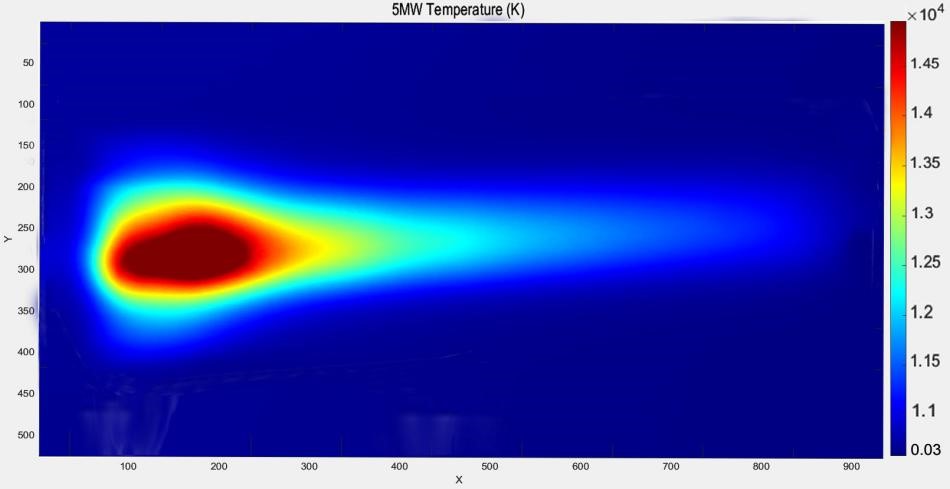

During the trial, researchers also performed the optical and electrical diagnostics of MW-level plasma torch, which was the world-first time. In addition, the test also established a new benchmark for the highest power reached by a single plasma torch.

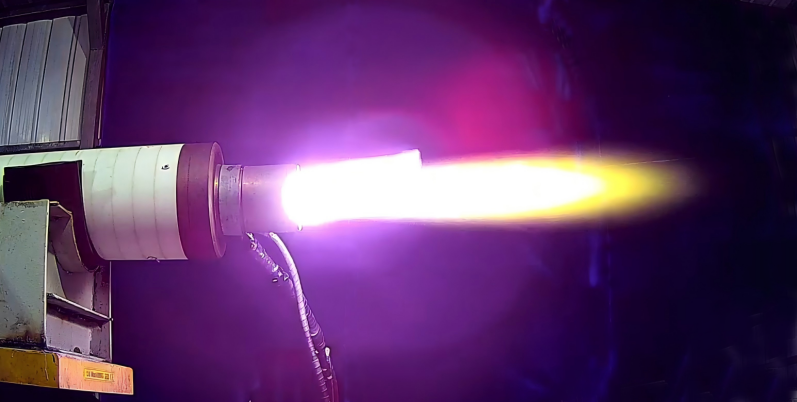

The 5 MW plasma torch, currently the largest single-unit plasma torch, is engineering-ready for industrial use. According to the team, performance targets were met or exceeded, including operational stability, reliability, and safety under high-load and complex working conditions. Temperature imaging and other diagnostic tools were employed to assess plasma characteristics throughout the test.

Thanks to the extremely-high temperature of tens of thousands degrees Celsius, the torch can supply a steady, high-temperature heat source for metallurgical furnaces. When integrated into iron-making processes, it is expected to partially replace fossil-fuel combustion, offering a cleaner and more controllable thermal environment. Its high plasma activity may also enhance the reduction-reaction depth and efficiency.

Prof ZHAO's team contributed plasma physics expertise accumulated through major scientific facilities such as the Experimental Advanced Superconducting Tokamak, helping address technical challenges in extending torch lifetime and achieving stable operation at high power. Baowu Equipment Intelligent Technology CO., LTD and Baowu Heavy Industries CO., LTD co-contributed in the long lifetime torch design and operation process, and supported the engineering implementation at site.

"If powered by renewable electricity, plasma torches could provide a route toward lower-carbon smelting," said Prof. ZHAO. The 5 MW torch test serves as an early technical verification step for exploring the feasibility of such applications in the steel industry.

5 MW plasma torch running during the 172-hour test. (Image by SU Yi)

Temperature distribution imaging of 5MW plasma torch physical diagnostics (Image by SU Yi)