The Science

Creating an efficient fusion plasma in a tokamak requires balancing competing temperature needs of the plasma – extremely hot in the core to allow fusion to occur but cool enough at the edge not to damage the walls of the device. An international team of researchers at the DIII-D National Fusion Facility has developed an innovative solution to this challenge that uses active injection of gases to cool the plasma in the edge region of an advanced tokamak plasma, reducing the heat before it reaches the walls of the tokamak. Even better, they have done this while maintaining high plasma performance in the core region.

The Impact

This new physics approach will be critical for future fusion reactors which will feature higher-power plasmas operating for extended periods of time. Current tokamaks like DIII-D operate for short pulses, after which the armor in the divertor – a region of the wall that dissipates heat and energetic particles along the top and bottom edges of the device – is allowed to cool. With sustained operations at higher power levels, future reactors will have to be even better at keeping the core hot while the divertor stays cool if they are to provide practical fusion energy.

Summary

The ability to fully cool plasma in the divertor while not reducing the performance of the core has eluded researchers for decades. To illustrate the scale of the challenge, temperature in excess of 100 million degrees Celsius are necessary for fusion in the core, but the solid walls of the tokamak can tolerate temperatures of only a few thousand degrees before the armor erodes and shuts down the fusion process.

Researchers have tried injecting radiative gases into plasma in the past and have achieved strong divertor cooling. Unfortunately, that same cooling often works its way from the divertor to the plasma edge to negatively impact a region of high confinement referred to as an edge transport barrier (ETB), thus reducing fusion performance. A transport barrier is a region of low plasma turbulence that functions as an insulating layer, significantly slowing the passage of particles or energy.

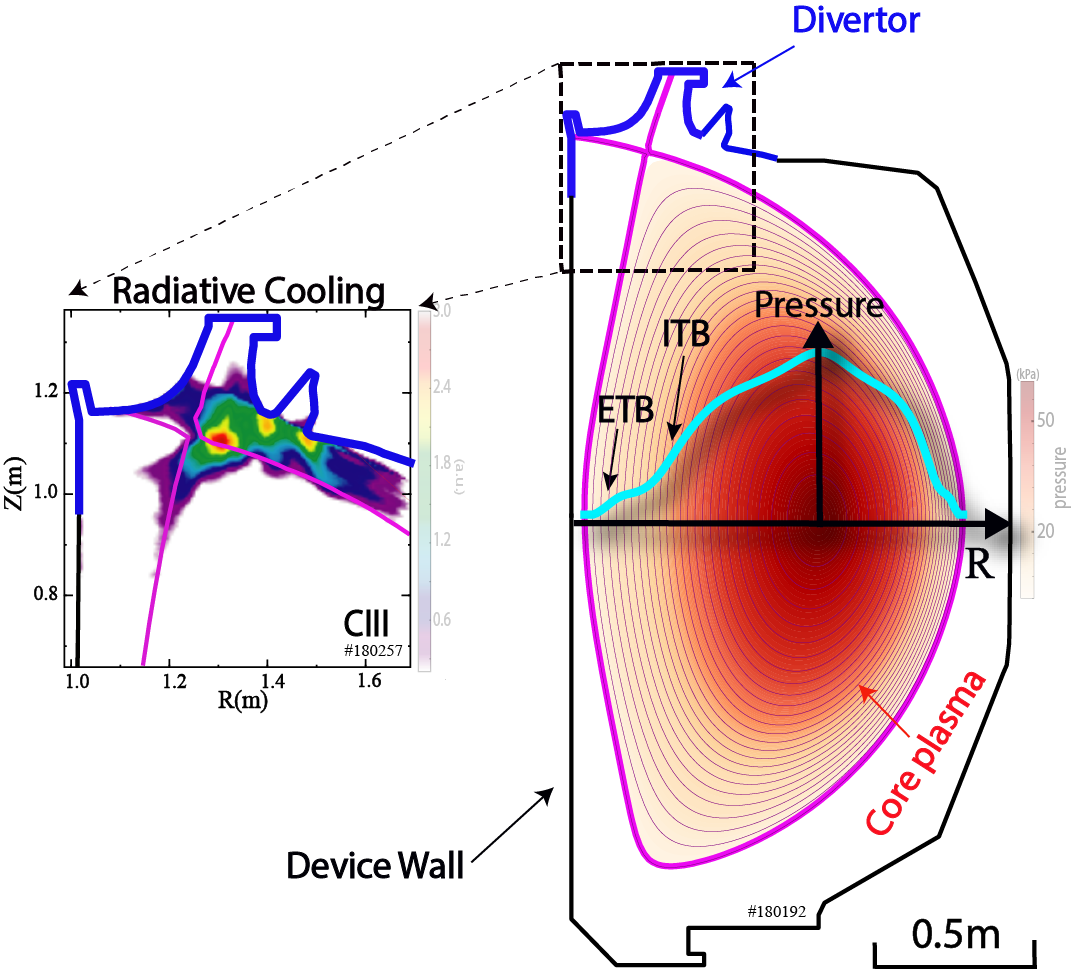

The DIII-D team, working with colleagues at China’s Experimental Superconducting Tokamak (EAST), Hefei Institute of Physical Science (HFIPS) , has shown promising results with a new approach that uses an additional transport barrier, further inside from the edge of the plasma, to isolate the hot core from the cooler edge (Figure 1). This internal transport barrier (ITB) is created by tailoring the shape of the plasma current in a way that is known to reduce plasma turbulence. When the injected radiative gases dissipate divertor heat and cool the edge transport barrier, this internal transport barrier is actually enhanced, improving the thermal isolation of the high-temperature core from the walls.

This work was supported by the Department of Energy Office of Science, Office of Fusion Energy Sciences, using the DIII-D National Fusion Facility, a DOE Office of Science user facility. It was also supported by the National Natural Science Foundation and the National Magnetic Confinement Fusion Science Program, both of China.

Link to the paper: Integration of full divertor detachment with improved core confinement for tokamak fusion plasmas

Figure 1 - Right: The DIII-D tokamak, showing the plasma shape and the contours plot of 2-D plasma pressure obtained in this study. The radial pressure profile is shown as the cyan curve. The internal transport barrier (ITB) and edge transport barrier (ETB) are labelled. Image courtesy of General Atomics

Left: Image courtesy of M. Fenstermacher, Lawrence Livermore National Lab. Contour plot of two-dimensional carbon radiation from inversion of a tangential-viewing camera.

Contact:

ZHAO Weiwei

Hefei Institutes of Physical Science (http://english.hf.cas.cn/)

Email: annyzhao@ipp.ac.cn