A kind of high-performance bulk pure tungsten with high strength and excellent ductility at low temperature, was fabricated recently by a collaborated research team from Institute of Solid State Physics, Hefei Institutes of Physical Science (HFIPS), Chinese Academy of Sciences (CAS), and Xi’an Jiaotong University.

The related research was published in Acta Materialia.

Tungsten (W) and its alloys have attracted much attention with its good performance. But pure W features an intrinsic brittleness and prone to operational embrittlement by grain coarsening and neutron irradiation.

In this research, through sintering the activated W powders by low-temperature sintering procedure, scientists obtained high-density bulk W slab with grain size of 8.9 μm. The subsequent warm working of HERF further refined the grains and constructed the lamellar matrix grains, with profuse interior fine sub-grains, and high density of mobile edge and mixed dislocations. The shielding and blunting effects from low-angle grain boundaries and highly mobile dislocations, and the lamellar structure reaped delamination toughening effect are the main mechanisms for the improved low-temperature ductility and strength.

The performance of this fine-grained bulk W was outstanding, according to the team.

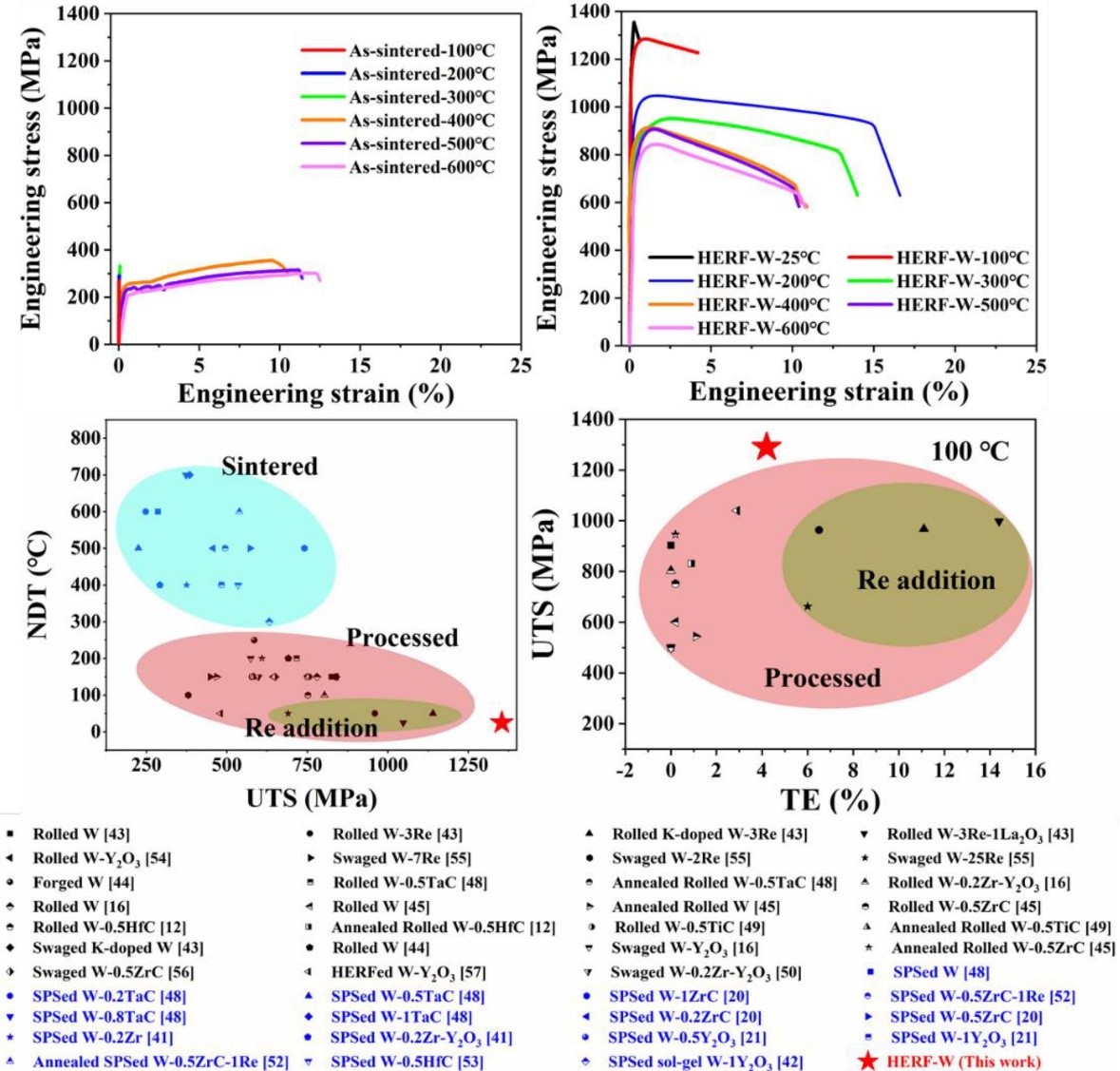

At room temperature, its yield strength is 1302 MPa, exceeded other reported bulk tungsten materials. Obvious tensile ductility was detected, which was the first time that tensile strain achieved at room temperature for bulk tungsten products.

Researchers also tested its tensile performance at high temperatures. The ultimate tensile strength and total elongation at 600 oC still maintained at a high level of 843 MPa and 10.2%, respectively. The strengths are much higher than that of previously reported bulk tungsten materials at tested temperatures.

"The grain was refined to about 1.3 μm," said WU Xuebang, who conducted the research, "which contributes to the brilliant low-temperature properties of this material."

He further explained structure of the bulk tungsten. Synergistic effect of lamellar elongated grain structures, high proportion of low-angle grain boundaries, and highly mobile dislocations ensured its improved low-temperature ductility and strength.

"The prepared high-performance bulk pure W has good application prospects in fusion reactors and high temperature industries," said WU, "and we believe this strategy is a feasible and low-cost pathway to design high performance refractory metals and alloys."

The work was supported by the National Key Research and Development Program of China, the National Natural Science Foundation of China, Anhui Provincial Natural Science Foundation and a HIRFL User Project.

Fig. 1. Schematic diagram of multi-scale microstructure modulation and sample pictures. (Image by XIE Xuefeng)

Fig. 2. Engineering stress-strain curves of sintered pure W and high-energy-rate forged pure W at different temperatures, and comparison of tensile properties of various W-based materials. (Image by XIE Xuefeng)