A recent study conducted by the research team at the Institute of Solid State Physics (ISSP), Hefei Institutes of Physical Science (HFIPS) of the Chinese Academy of Sciences (CAS) successfully synthesized a high-entropy boride ceramic material. It has exceptional abilities, including high thermal emissivity of 95% in the visible and near-infrared spectral range, along with a remarkable hardness exceeding 30 GPa.

These findings were published in Journal of the European Ceramic Society.

Ultra-high temperature boride ceramics are promising materials for extreme environments, but they are vulnerable to oxidation and ablation in strong oxidation flow environments. To tackle this, materials with high thermal emissivity are used to reduce temperature differences and enhance resistance. Borides also tend to fracture under thermal shock due to low damage tolerance. High-entropy borides offer a solution, but many details are still unclear, such as powder design, solid solution mechanism, factors enhancing thermal emissivity, and densification processes.

To address these challenges, the researchers followed high-entropy design principles. They selected titanium (Ti), zirconium (Zr), niobium (Nb), molybdenum (Mo), and hafnium (Hf) as the key elements for this special material.

Using flocculation-precipitation method, researchers created tiny powders, averaging 495 nanometers in size, with very low levels of carbon and oxygen.

With X-Rays, they found that the material went through two stages to form a single-phase solid solution.

First, metal oxides turned into intermediate diborides, which then acted as a base for the other metals, creating the final material.

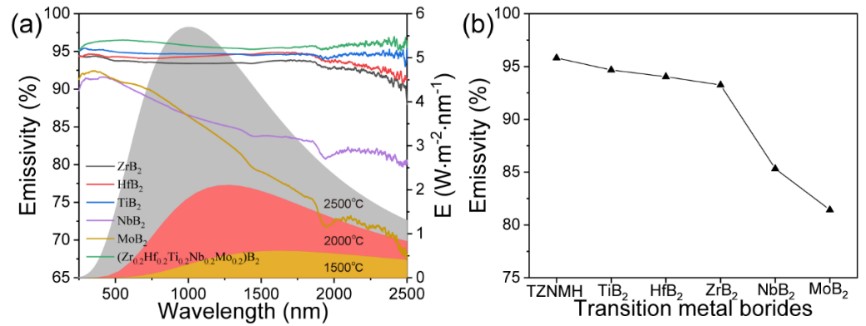

Even at normal room temperature, these powders could radiate heat really well, almost like a black body. They had a very high thermal emissivity, meaning they could release heat efficiently across a wide range of wavelengths.

Computer simulations showed that the material's special mix of elements was what made it so good at releasing heat.

The nearly fully dense TZNMH bulk was prepared. It exhibited an extremely high hardness. It stayed tough even after being heated to 1800°C for 60 hours, attributed to the strong hybridization between metals and boron.

This work elucidates the design principles and solid solution mechanism of high-entropy boride ceramics, providing alternative solutions for high-performance thermal protective materials.

Researcher is taking synthesized high-entropy ceramic powders out from the high-temperature calcination furnace. (Image by DANG Xian)

Fig. 1 Preparation process and microstructure of TZNMH. (Image by Dang Xian)

Fig. 2 Radiation characteristics of TZNMH and the five individual diborides. (Image by Dang Xian)