A research group led by Prof. PENG Xuebing from the Hefei Institutes of Physical Science of the Chinese Academy of sciences proposed a concept design of a combined cycle system for the fusion reactor based on Rankine and Brayton cycle to overcome the high outlet temperature and long run of the fusion reactor.

The results have been published in the Journal of Case Studies in Thermal Engineering.

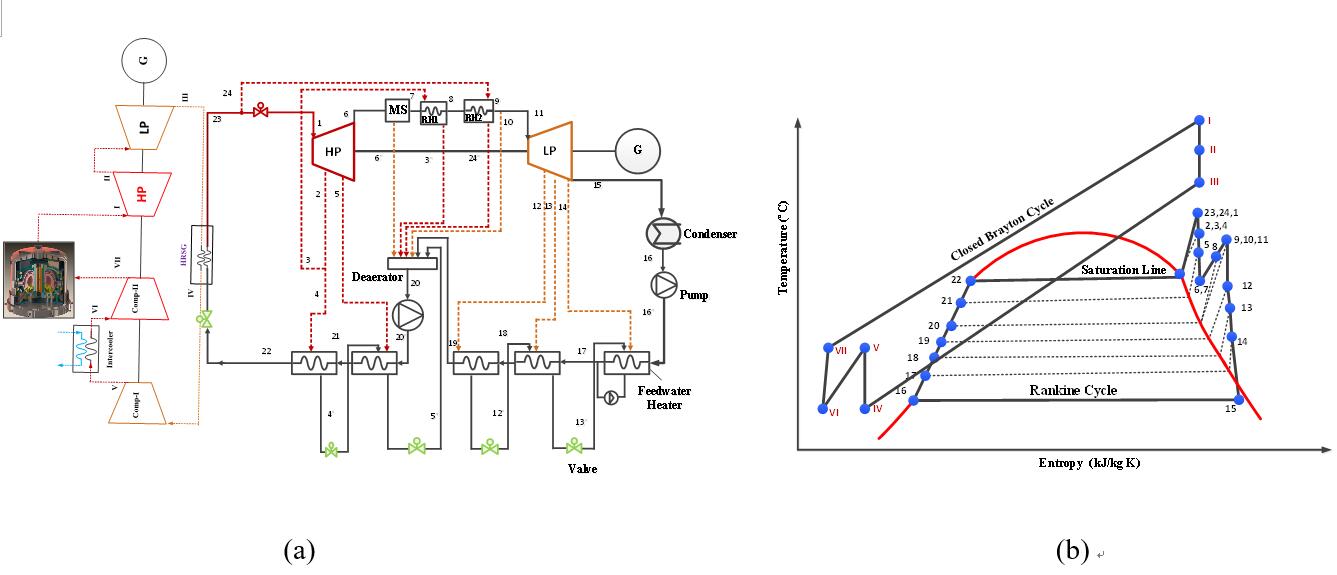

One of the main challenges for fusion reactors is achieving high thermal performance in their power generation systems due to the high temperatures involved. The proposed combined cycle system addresses this by incorporating two stages of expansion in a closed-Brayton cycle and two reheaters in a Rankine cycle. This design achieves a thermal efficiency of 58.19%.

In this study, researchers developed a thermodynamic model for this system using MATLAB and the Energy Equation Solver tool, basing it on principles of energy conversion and thermodynamics. They discovered that adding more than one expansion and reheat stage is not cost-effective, as it only marginally increases thermal performance compared to a single stage.

To validate their model, the team studied the impact of the compressor's isentropic efficiency and the system's heat rate. They found that the optimal thermal performance of 58.19% is achieved at a feed water mass flow rate of 592 kg/s and a steam outlet temperature of 277°C. As the mass flow rate increases, the heat rate decreases and thermal performance improves, confirming the accuracy of their model.

This Combined Cycle Nuclear Power Plants concept design can be used as a reference for design optimization and evolution of the efficient system for the fusion reactor based on the concept of different numbers of expansion, compressions, reheat stages along with optimization of parameters of the plant.

Fig.1 (a) Schematic of Power Conversion System (b) T-S diagram of the system (Image by Salman)