A recent study led by Professor YIN Huajie from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences, introduces an innovative way to improve esterification reactions, which are key processes in industries like chemistry, perfumery, and pharmaceuticals.

The new method, published in Advanced Materials, uses a system, Joule heating interface catalytic (JIC), to make the reaction much more efficient.

Esterification reactions are important, but they come with challenges. These reactions tend to be reversible and have low reactivity, meaning it's hard to get high yields. Traditional methods often require adding extra alcohol or dehydrating agents, which can be expensive, wasteful, and make it harder to separate the products.

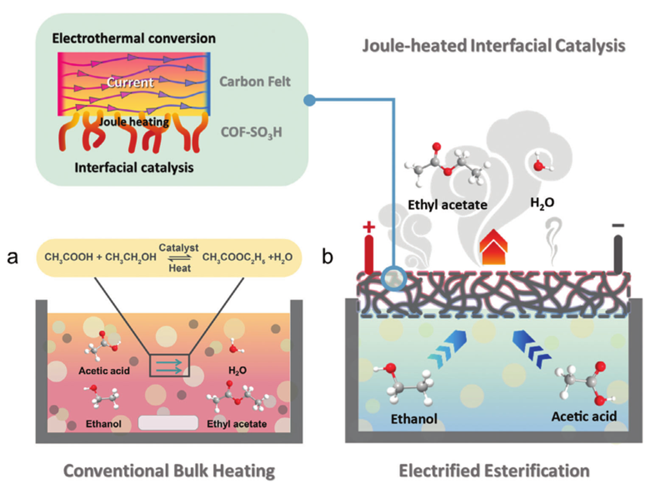

To overcome these challenges, the researchers developed a new electrified esterification pathway using the JIC system.

"What' s special here is that it uses the electrothermal source and catalyst together," said Prof. YIN.

This system combines Joule heating and interface catalysis, which helps separate products directly during the reaction and speeds things up. The JIC system uses a special catalyst made of a sulfonic acid-functionalized covalent organic framework (COF-SO3H) and carbon felt as an electrothermal source. Under the right conditions, with a 1:1 ratio of reactants, the system achieved an impressive 80.5% conversion rate of acetic acid—much higher than the theoretical limit of 62.5%.

This study not only improves the efficiency of esterification reactions but also provides an energy-efficient, sustainable way to drive high-yield chemical processes.

a) Conventional Bulk Heating (CBH) method. b) Joule-heated interfacial catalysis (JIC) system for electrified esterification. (Image by YIN Huajie)