Recently, the research team led by Researcher WANG Guozhong from the Institute of Solid State Physics, the Hefei Institutes of Physical Science of the Chinese Academy of Sciences, has developed a method to precisely control the size of nickel particles in catalysts, improving their performance in hydrogenation reactions.

The related research results were published in Advanced Functional Materials.

Catalysts are essential in speeding up chemical reactions without being consumed, and the size of the metal particles in them plays a key role in their effectiveness. Larger particles have more high-coordination sites, while smaller ones are dominated by low-coordination sites. These different sites play distinct roles in catalytic reactions.

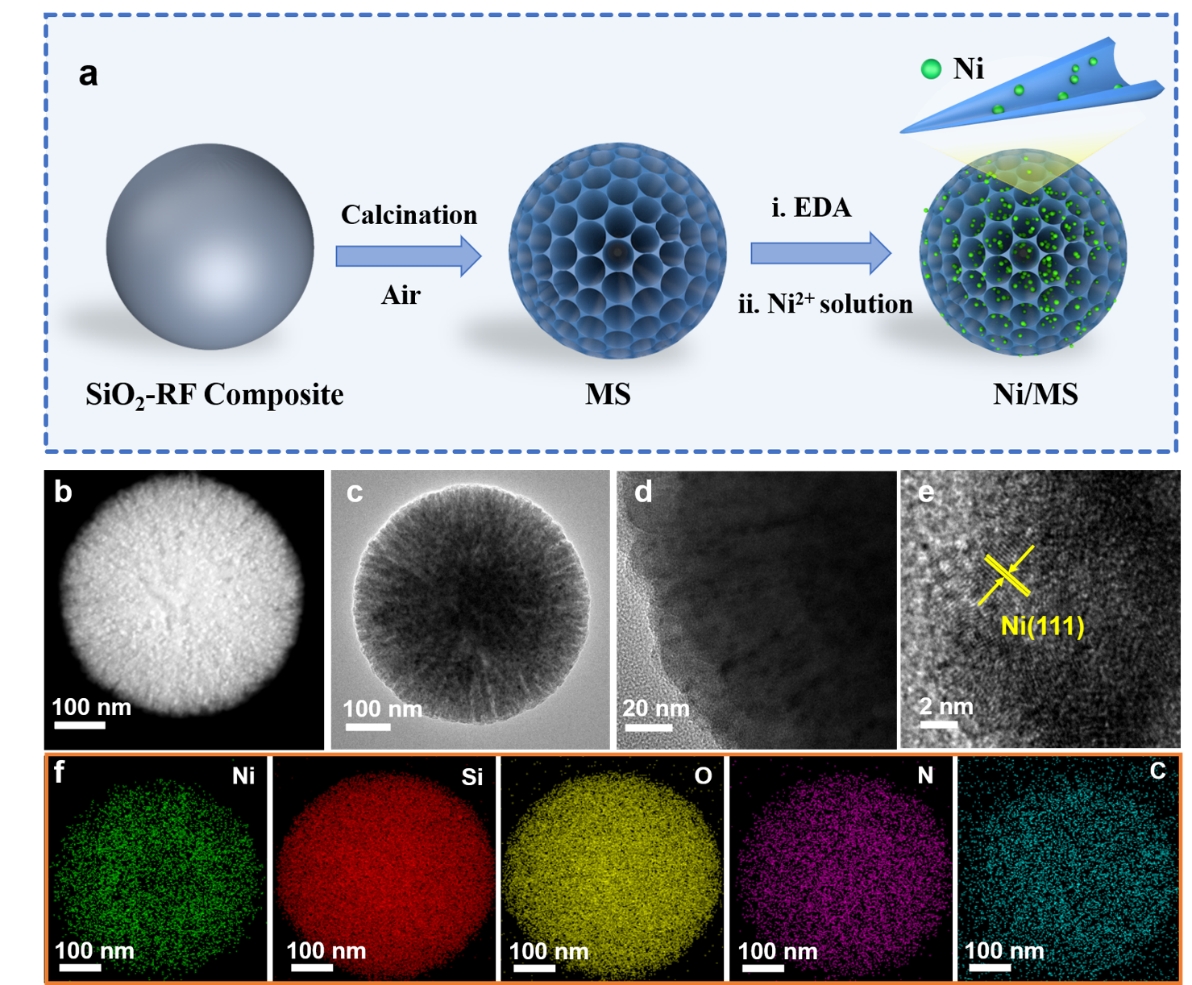

In this study, the team synthesized mesoporous silica and used a strategy that adjusted the molar ratio of ethylenediamine (EDA) to nickel (Ni) to create Ni/MS catalysts with varying Ni particle sizes. They then explored how these particle size variations affected the hydrogenation performance of vanillin and examined the underlying reaction mechanisms using both experimental and theoretical approaches.

By adjusting particle size, researchers can optimize catalyst performance and product selectivity, though finding precise control methods has been challenging.

In this work, the team applied a hybrid strategy of amino-modification and vacuum-impregnation to prepare Ni/MS catalysts with controlled Ni particle sizes ranging from 2.2 to 12.6 nm. They found that the hydrogenation of vanillin into 2-methoxy-4-methylphenol (MMP) showed a peak productivity with the Ni/MS-4.8 catalyst, which had intermediate-sized particles. Their findings highlight that low-coordinated Ni atoms aid in the adsorption of reactants such as hydrogen and vanillin, while high-coordinated atoms facilitate hydrogen dissociation.

This research provides valuable insights into optimizing catalyst design for improved hydrogenation reactions.

The structure of the Ni/MS-4.8 catalyst: (a) schematic illustration of the synthesis procedures, (b) HAADF-STEM, (c) TEM, (d, e) HRTEM image and (f) EDS mapping images. (Image by ZOU Zidan)