A research team at the Institute of Solid State Physics, the Hefei Institutes of Physical Science of the Chinese Academy of Sciences, has recently developed advanced aerogel composites that combine high-temperature insulation with mechanical load-bearing capabilities, while also achieving controllable fabrication of large-size samples.

The findings were published in Materials Today Energy and Journal of Materials Research and Technology.

High-performance systems are increasingly exposed to extreme environments. This creates a growing demand for insulation materials that are lightweight, mechanically robust, thermally efficient, and stable under high temperatures. While traditional aerogels are known for their excellent thermal insulation and ultra-low density, their weak mechanical strength, poor stability at elevated temperatures, and difficulties in large-scale production have greatly limited their practical use.

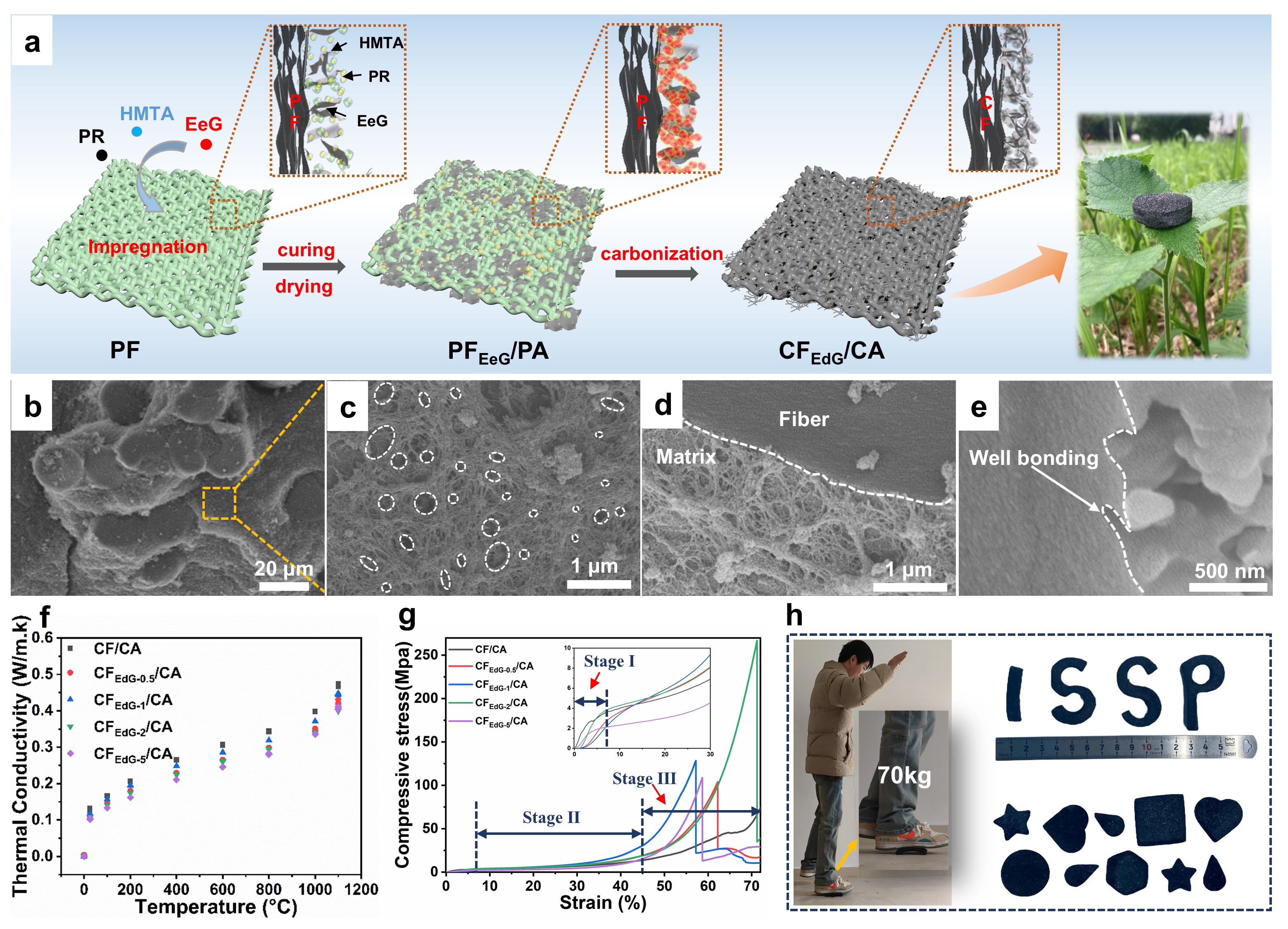

To address these challenges, the research team built upon their previous work and developed a carbon fiber reinforcement strategy to create high-performance aerogel composites. By introducing expandable graphite as an interfacial bonding agent, they constructed a robust multi-scale framework that significantly enhanced structural integrity and resistance to thermal deformation. The resulting composites maintained mechanical strength under load while providing efficient thermal insulation across a wide temperature range.

In parallel, for ceramic-based aerogel composites, the team proposed a novel precursor impregnation and in-situ dual-morphology growth technique. This approach enabled the simultaneous formation of dense silicon carbide coatings and a network of nanowires within the carbon fiber structure, greatly improving oxidation resistance and ablation performance. Even after exposure to extremely high temperatures, the composites retained their lightweight structure, mechanical strength, and excellent thermal insulation properties, demonstrating strong potential for future thermal protection applications.

Importantly, both types of composites demonstrated the feasibility of large-size fabrication, with samples successfully prepared and capable of being cut and processed as needed.

These progresses provide new technical pathways for the engineering applications of aerogel composites.

The synthesis schematic (a), microstructure characterization (b-e), thermal conductivities at different temperatures (f), stress-strain curves (g) and molding performance (h) of the carbon-based aerogel composites. (Image by YU Jie)