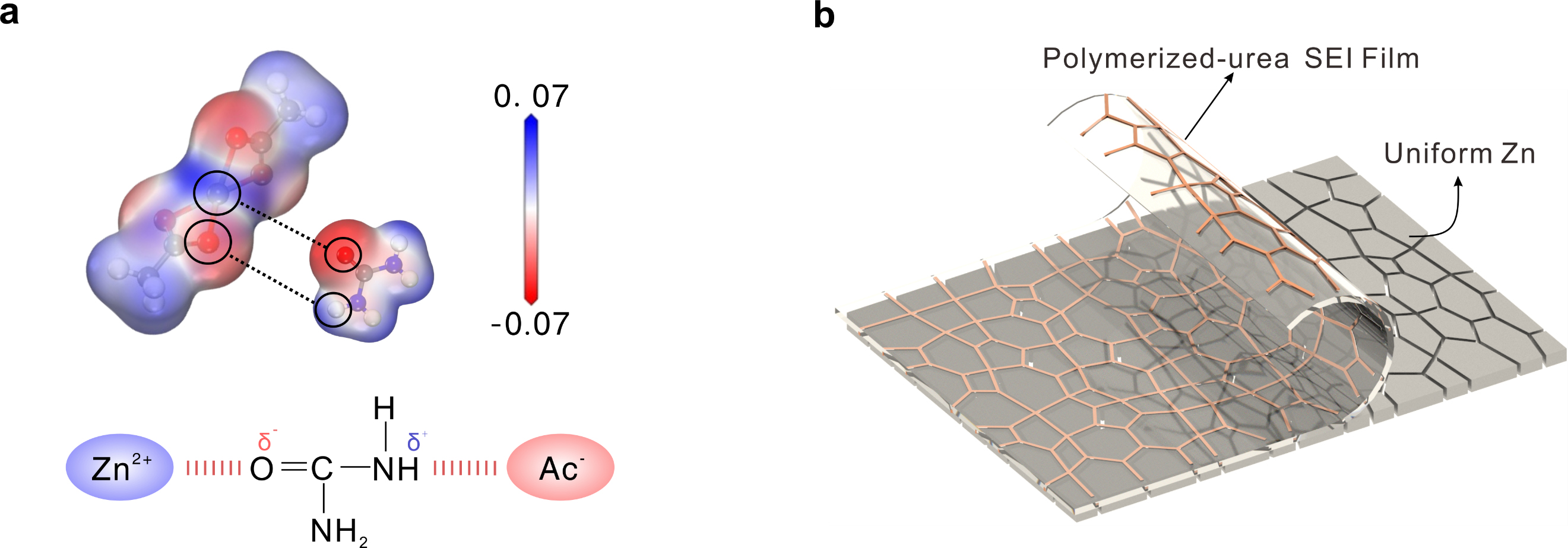

According to research published in Angewandte Chemie International Edition recently, a team led by Prof. HU Linhua. from Hefei Institutes of Physical Science of the Chinese Academy of Science develop a high mechanical durability hydrogel electrolyte using urea as a zincophilic solubilizer and Zn(Ac)2 salt for its low cost and eco-friendly traits. As-prepared hydrogels can sustain 557% tensile elongation and 3.7 MPa compressive strength. In-situ polyurea solid electrolyte interphase (SEI) formed during aqueous zinc-ion batteries (AZIBs) operation allows for stable Zn stripping/plating in a dendrite and passivation-free manner.

"This approach overcomes the usual limits of the low-cost Zn(Ac)2 salt, making it much better at resisting wear and tear," said LI ZHAO Qian, a member of the team, "It allows the material to withstand repeated processes of zinc plating and stripping, as well as other physical stress, improving its overall durability.”

Aqueous zinc-ion batteries struggle with electrolyte leakage and corrosion. Quasi-solid-state electrolytes offer stability and flexibility, but current research often overlooks cost and toxicity, while fatigue resistance remains an issue. Zinc acetate is low-cost and eco-friendly but poorly soluble, limiting battery capacity and performance. Improving its solubility and using it in quasi-solid-state electrolytes is key to enhancing mechanical durability and capacity.

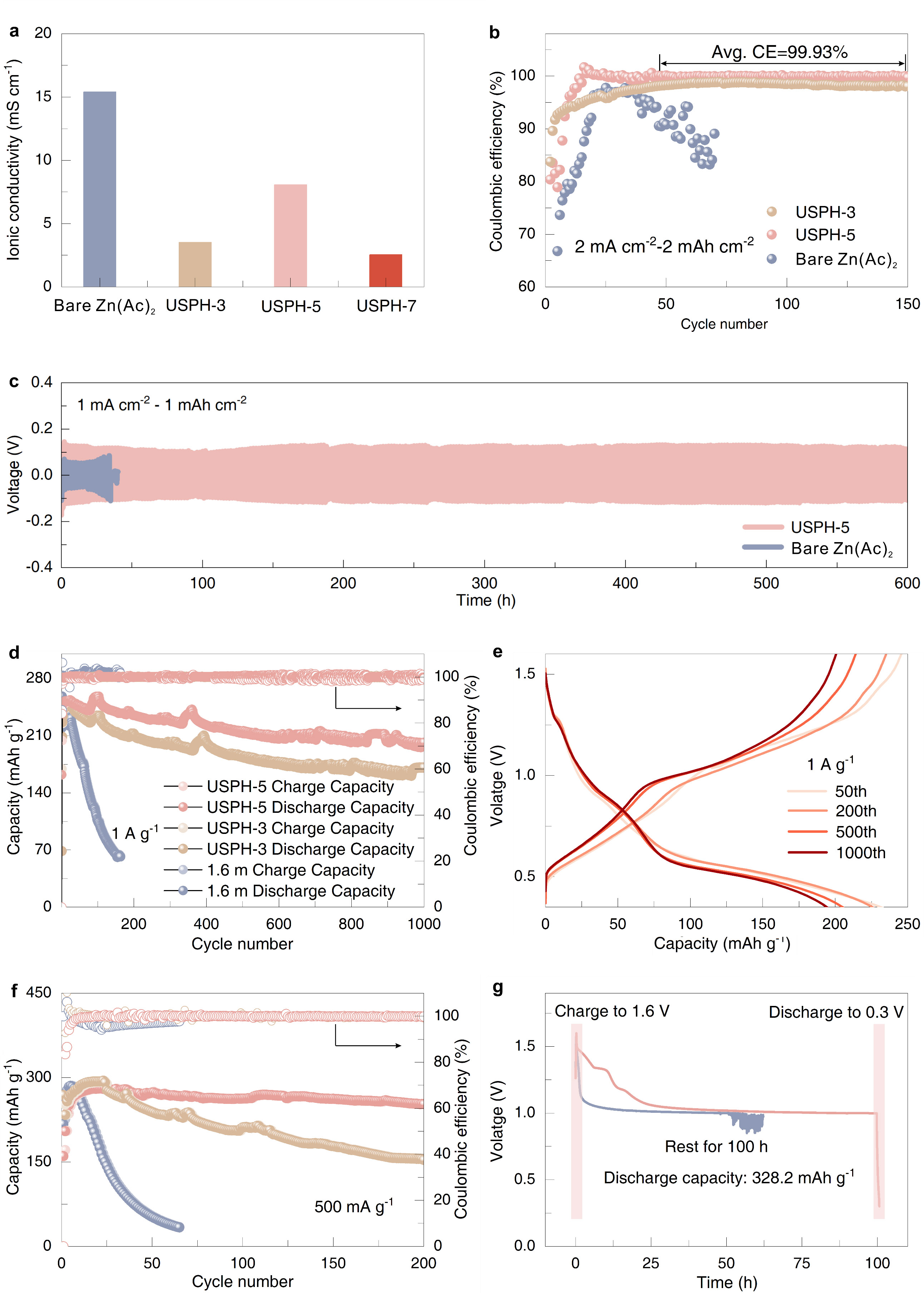

In this study, researchers applied a special strategy to enhance the solubility of zinc acetate in the electrolyte, allowing for higher concentrations. This process, known as the ‘salting out’ effect, helps to remove hydration layers from polymer chains and strengthens their connections. As a result, the material becomes much more resistant to fatigue, meaning it can better handle repeated cycles of zinc deposition and stripping, as well as external physical stress. During battery operation, a protective layer naturally forms on the electrode, improving the overall stability of the battery’s interface. The zinc-ion battery shows excellent efficiency, and the flexible pouch cell performs well in terms of capacity and stability, even after many cycles. The flexibility of the pouch cell is particularly notable, as it can maintain a steady voltage even when bent or folded, making it suitable for use in portable and wearable devices.

“When the flexible pouch battery is subjected to varying degrees of bending, it still retained a stable voltage even at 180°. These findings highlights its potential for application in portable and wearable electronic devices,” explained Dr. LI Zhaoqian.

The researchers also evaluated the battery's performance in terms of rate capability and self-discharge. The full Zn//NH4V4O10 battery with the USPH-5 electrolyte showed excellent capacity, even after repeated cycling. After a long rest period, it still delivered a strong discharge capacity, while batteries without the USPH-5 electrolyte showed a significant loss in capacity. This demonstrates that the new electrolyte material greatly enhances the battery’s overall performance and retention over time.

This research not only highlights the zincophilic solubilization to break salt solubility limit in quasi-solid-state AZIBS, but also provides an extendable regulation strategy for other metal anodes to fulfill low cost, eco-friendly and high-performance batteries.

The research has been supported by the HFIPS Director's Fund, the Anhui Provincial Natural Science Foundation and the Anhui Provincial Science and Technology Innovation Initiative.

Figure 1. (a) Calculated electrostatic potential (ESP) distribution of Zn(Ac)2 and urea, and schematic representation of the Zn2+-urea-Ac- system. (b) Schematic illustration about the uniform Zn deposition by using the USPH-5. (Image by LI Zhaoqian)

The properties comparison of different electrolytes (Image by LI Zhaoqian)