Lead-based reactor is the most promising one among Gen-IV nuclear reactors, but its coolant, i.e. lead-bismuth eutectic alloy (LBE), has serious corrosive effect on structural materials at high temperature or velocity. When the oxygen concentration in LBE is controlled to an appropriate level, a protective dense oxide scale, which separates structural materials from LBE, will be formed on the surface of structural materials to resist the corrosion. However, the external stress caused by the load and thermal cycle may lead to the rupture and failure of the oxide scale during long time operation.

Recently, a research team led by Prof. HUANG Qunying, from Institute of Nuclear Energy Safety Technology, Hefei Institutes of Physical Science, studied the effect of stress on oxide scale of lead-based reactor materials and established a model to explain the phenomenon.

To study the process, the research team designed a small tapered conical specimen based on the “high throughput method”. They studied the cracking and exfoliation behavior of the oxide scale on martensitic steel T91 specimen with the self-developed slow rate tensile test system in LBE.

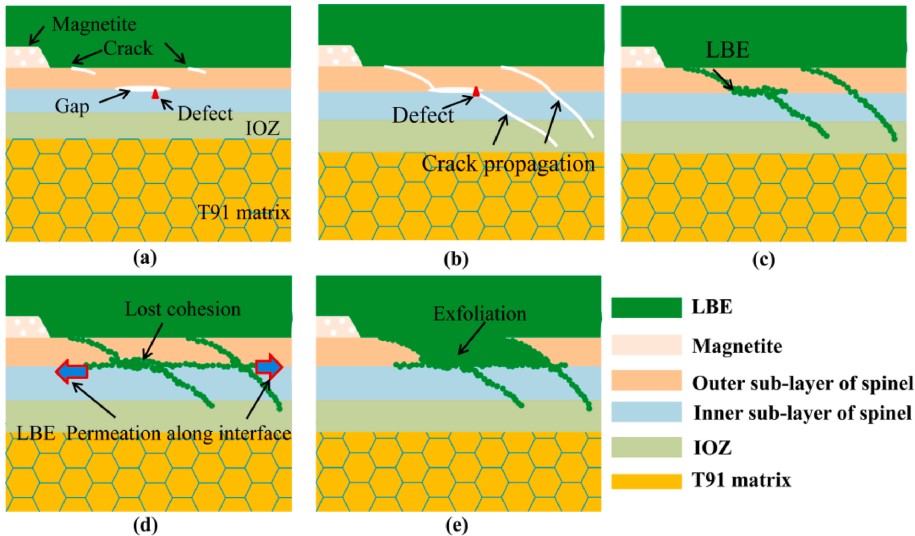

"We found that the magnetite layer, which was located in the outermost layer of oxide scale, would fall off gradually with the increase of tensile stress,” said LUO Lin, one of the key staffs of the research team, “When the stress at the concave of the specimen exceeded a certain threshold, the protective spinel layer would crack band-like and the outer sub-layer of spinel partially exfoliate.”

Moreover, the cracks with four different morphologies originated at the outer sub-layer of spinel and propagated inward. Some cracks in spinel extended in the form of arc and step combination.

"We established a model,” said LUO excitedly, “to explain the cracking and exfoliation for the outer sub-layer of spinel.”

This study shows that the protective oxide scale in the concave parts of component will firstly fail, which should be paid more attention in the structural design and safety analysis of lead-based reactor.

This work is funded by the National Key R&D Program of China and the National Natural Science Foundation of China.

Link to the paper: Cracking and exfoliation behavior of oxide scale on T91 steel under different tensile stresses in oxygen-controlled lead-bismuth eutectic at 550 °C

Fig. 1. Liquid metal slow strain-rate tensile system (Image by LUO Lin)

Fig. 2. Schematic diagram for cracking and exfoliation of spinel layer under the synergistic effect of LBE and tensile stress. (Image by LUO Lin)

Contact:

ZHAO Weiwei

Hefei Institutes of Physical Science (http://english.hf.cas.cn/)

Email: annyzhao@ipp.ac.cn