Recently, researchers from the Institute of Solid State Physics, Hefei Institutes of Physical Science (HFIPS), Chinese Academy of Sciences studied the equivalence of the continuous heating and isothermal recrystallization process and proposed a new method to determine the recrystallization temperature by internal friction measurement and the formed mechanism of recrystallization internal friction (IF) peak.

The related results were published in Journal of Alloys and Compounds.

The recrystallization temperature is important to properties and performance of materials in reference to the microstructure it depends largely on. The traditional methods, including metallographic and hardness methods, need a large number of samples in the process, and have disadvantages such as tedious operation, long test cycle, and high material cost.

IF technique, sensitive to the defects in solids, can be used to study the changes of microstructure in solid materials and the recrystallization process of the deformed metals. However, the peak temperature of the recrystallization IF peak occurred in heating process depended upon the heating rate and largely differs from the classical recrystallization temperature determined by the isothermal annealing process.

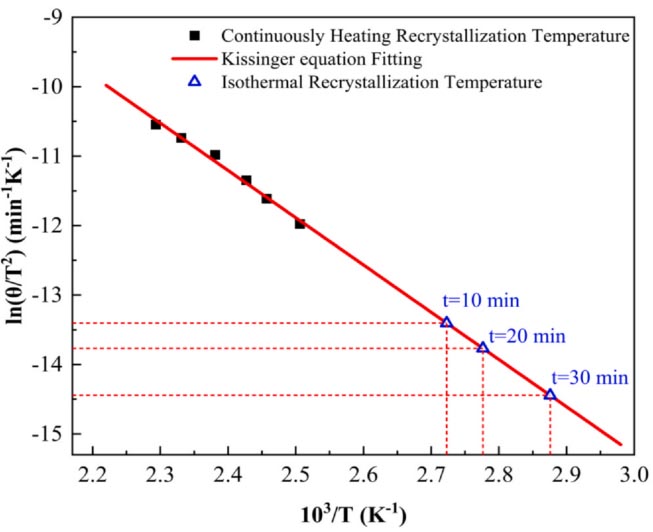

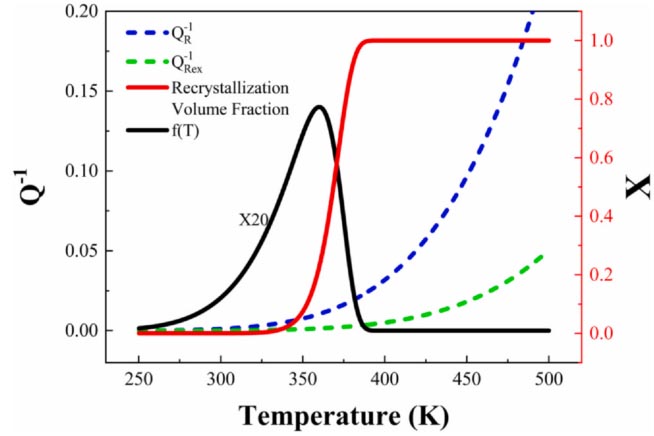

In this research, researchers studied the behavior of recrystallization of deformed high purity Al in continuously heating process by IF technique, and observed a non-relaxation peak associated with the recrystallization process. With the increasing measurement frequency, this IF peak decreases in height but does not change in position., However, it shifts towards higher temperature with the heating rate. Meanwhile, the formation mechanism of the recrystallization peak in the deformed high purity Al was analyzed and the corresponding formula was supposed. Consequently, the Kissinger equation of the recrystallization in the process was set up which links the IF peak temperature and heating rate.

Combined with the isothermal recrystallization temperature determined by hardness method which exhibits the same apparent activation energy, the equivalent method of IF peak temperature and isothermal recrystallization temperature was suggested, i.e. the isothermal recrystallization temperature corresponding to the annealing time (10, 20, and 30 min) can be determined from the above-mentioned Kissinger equation just by substituting the corresponding heating rate (0.20, 0.14 and 0.064 oC/min) to the equation.

Compared with the classical isothermal method, this new method via IF measurements could evaluate the recrystallization temperature more accurately with a less quantity of samples, and thus is much easier and faster.

"It’s a good way to determine the recrystallization temperature by IF technique," said FANG Qianfeng, who led the team, "We have the faith that it can be generalized to other deformed metals such as Cu alloys and steels."

The above work was supported by the National Key RESEARCH and Development Program of China, the National Natural Science Foundation of China and the President's Foundation of HFIPS.

Figure 1. Correlation of the isothermal recrystallization temperature (open triangles) with the continuously heating recrystallization temperature (solid squares) via Kissinger equation (red line).(Image by FANG Qianfeng)

Figure 2. An example of crystallization volume fraction (red), and IF values of the recrystallization peak (black), the rolled (green) and fully recrystallized (blue) states versus temperature. (Image by FANG Qianfeng)