Recently, in collaboration with High Magnetic Field Laboratory at the Hefei Institutes of Physical Science of Chinese Academy of Sciences, a research group led by Prof. JIANG Chengbao and Prof. WANG Jingmin from Beihang University developed a Ni34Co8Cu8Mn36Ga14 single crystal that exhibited giant magneto-superelasticity of 5%. This means the crystal can return to its original shape after being deformed, triggered by a magnetic field rather than physical stress.

The research results were published in Advanced Science.

Elasticity is a material's ability to return to its original shape after deformation. Most metals can do this up to a strain of about 0.2%. Some special alloys, like shape memory and high entropy alloys, can exhibit superelasticity, where they can endure much larger strains and still return to their original shape. Typically, this is triggered by applying external stress. Magneto-superelasticity, however, is induced by a magnetic field, which opens up new possibilities for designing contactless devices and efficient energy transducers.

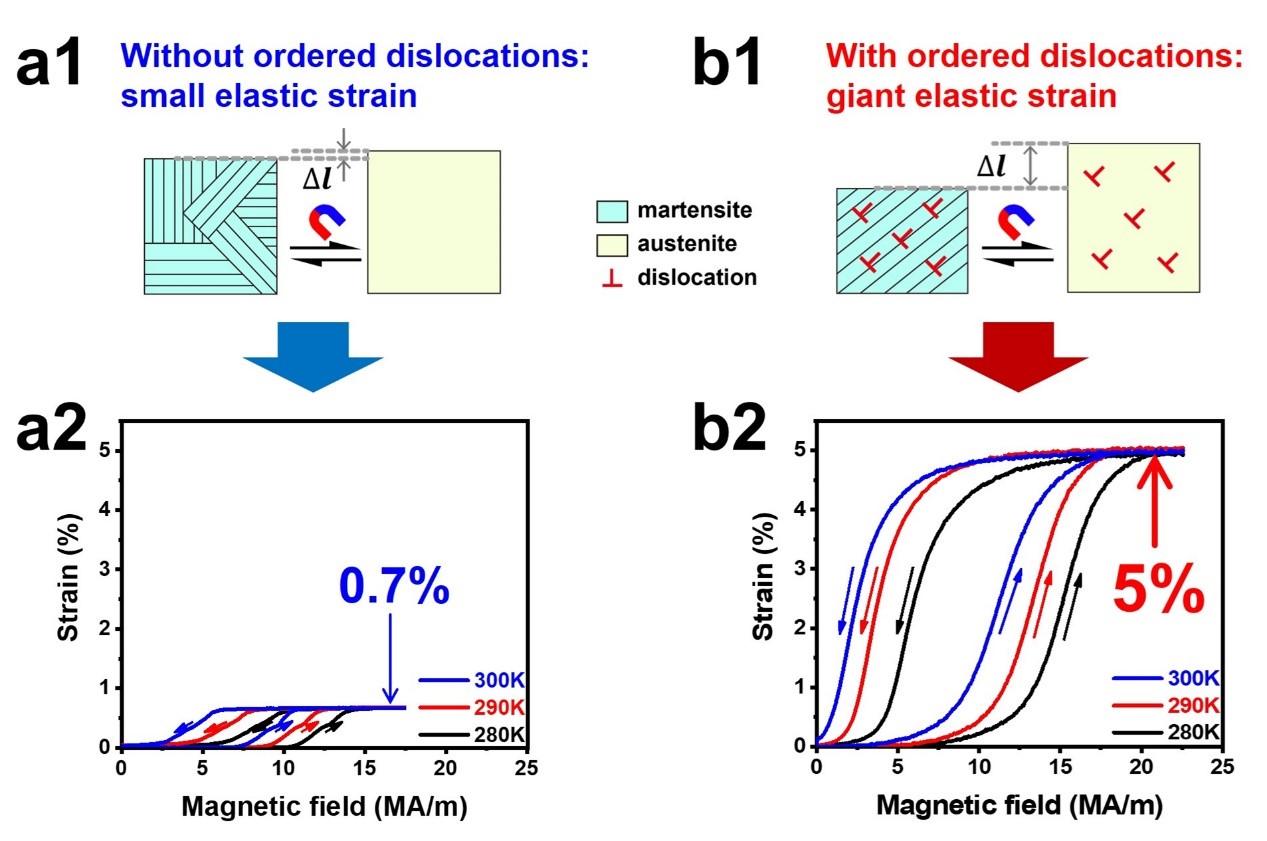

In this study, researchers performed a stress-constrained transition cycling (SCTC) training for the Ni34Co8Cu8Mn36Ga14 single crystal. They applied compressive stress, which introduced arrays of ordered dislocations—defects in the crystal structure that were oriented in a specific way. These dislocations played a crucial role in forming specific martensitic variants, which are particular arrangements of atoms that occur during a reversible transformation induced by a magnetic field.

Using phase field simulations, the team confirmed that the internal stress generated by these organized dislocations helped shape these preferred martensitic variants. This combination of reversible martensitic transformation and preferential orientation allowed the single crystal to achieve a remarkable 5% magneto-superelasticity.

To showcase the potential of this material, the researchers designed a device that uses a pulsed magnetic field. With a pulse width of 10 milliseconds, the device achieved a significant stroke at room temperature, thanks to the crystal's giant magneto-superelasticity. It also demonstrated a rapid response to an 8-millisecond pulse, with only a 0.1-millisecond delay.

"Our work provides an attractive strategy to access high performance functional materials by defect engineering.," said Prof. Wang.

Magneto-elasticity of the Ni34Co8Cu8Mn36Ga14 single crystal. a1) and b1) Schematic illustration of self-accommodated and preferentially oriented martensitic variants without and with ordered dislocations. a2) and b2) The corresponding experimental results on the small and giant magnetoelastic strain, respectively. (Image by YU Qijia)