In a review paper recently published in Journal of Nuclear Materials, Prof. HUAUG Qunying from Hefei Institutes of Physical Science (HFIPS) of Chinese Academy of Sciences (CAS), together with other research teams, introduced the latest development and strategy on fusion energy in China briefly and reviewed the progresses of research and development (R&D) activities on the reduced activation ferritic/martensitic (RAFM) steel, aiming for the engineering applications.

Fusion programs are being widely performed in China to push the final application of clear fusion energy. Test blanket module (TBM) for the international thermonuclear experimental reactor (ITER) is the key component to verify energy extraction, tritium breeding and its self-sustaining. Therefore, high standard for structural material of fusion reactor is required to meet the harsh operation environment, including high energy neutron irradiation, high heat flux impact, complex electromagnetic and mechanical loads.

"RAFM steel has many advantages," explained Prof. HUANG Qunying, "like low activation, good radiation resistance and high temperature mechanical properties and relatively mature industrial technologies. That's why it's chosen as the promising structural material for ITER-TBM and fusion DEMO reactor."

In this paper, they summarized the improvement of properties and key technologies development for final application in ITER and CFETR in China during the past few years.

According to the paper, the latest studies and progresses mainly focused on composition design, radiation resistance and mechanical properties optimization, processing and forming technologies, standardization construction and engineering qualification.

Among all the progresses, Prof. HUANG mentioned the most important one. "The key technologies have been pushed forward very quickly under the supports on R&D of RAFMs and TBM. Some related standards have been issued." she said, "With these profound technologies and experiences, we are closer to the final engineering application of RAFM steel in ITER, CFETR and DEMO."

These studies and progresses laid a solid material and technical foundation for the fabrication of ITER-TBM. It also provided important reference for the R&D of other RAFMs, ITER-TBMs, and the blanket modules of CFETR and DEMO.

The work was funded by National Key Research and Development Program of China, Chinese Helium Cooling Ceramic Test Blanket Module Project, Joint Funds of the National Natural Science Foundation of China and International Partnership Program of Chinese Academy of Sciences etc..

Figure 1. Fatigue and creep properties of 9Cr-RAFM steels and welded joints. (Image from Refs. [48,28])

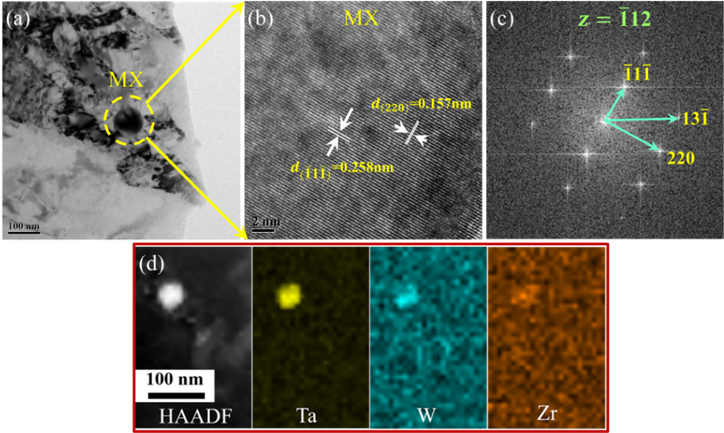

Figure 2. Microstructure and precipitated phase of modified RAFM steel. (Image from Ref. [14])

Figure 3. Half prototype of HCCB-TBM (Image by Southwestern Institute of Physics)