Recently, researchers from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences elucidated the structural evolution of Y2Ti2O7 during the preparation process of oxide dispersion strengthened (ODS) steel, and proved the feasibility of regulating the properties of ODS steel by controlling the initial structure of oxide.

The research results were published in Journal of Nuclear Materials.

China Low Activation Martensitic (CLAM) steel has been selected as one of the main candidate structural materials for fusion reactor blanket due to its good mechanical properties and relatively mature fabrication technology in China. The upper temperature of martensitic steel is usually limited to 550 ℃. In order to improve the thermal efficiency and safety of nuclear reactors, it is necessary to further increase the upper temperature of structural materials, and oxide dispersion strengthening is one of the effective methods.

In this study, researchers made two types of ODS-CLAM steel samples: one with nano-Y2Ti2O7 and the other with amorphous Y2Ti2O7. They investigated the structural evolution with different initial structures and its effects on structure and properties of the material.

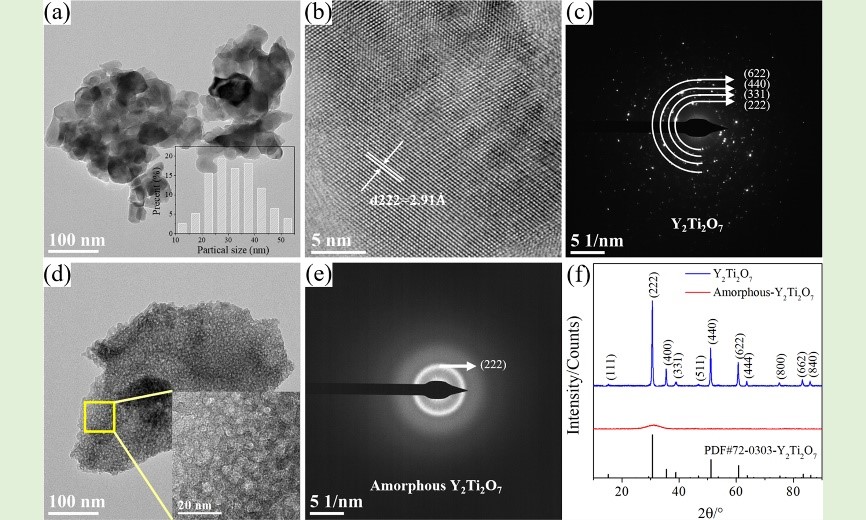

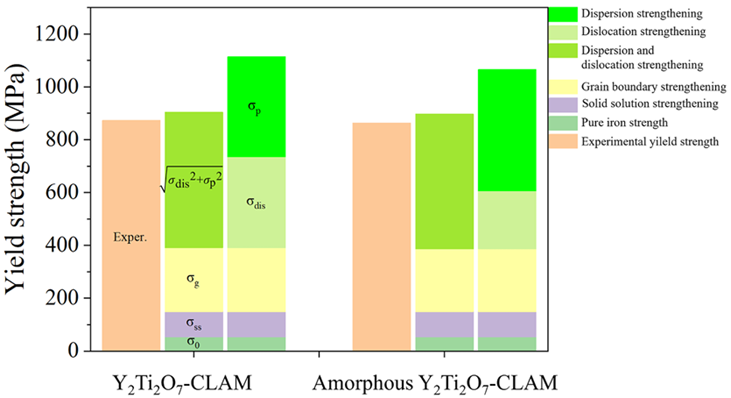

The results showed that the amorphous Y2Ti2O7 was partially converted into crystalline oxides after ball milling, and the structure of nano-Y2Ti2O7 did not change during the ball milling process. Due to the finer nano-oxide distribution, the sintered sample added amorphous Y2Ti2O7 had higher plasticity while it retained similar yield strength than the sample added nano-Y2Ti2O7.

This study provides a reference for the research and development of strong plastic ODS steel, according to the team.

Figure 1 Initial structure of added Y2Ti2O7 oxide: (a-c) nano-powder; (d-e) amorphous powder; (f) XRD pattern (Image by HUANG Tingjun)

Figure 2 Comparison of measured and calculated yield stress of two tempered samples (Image by HUANG Tingjun)