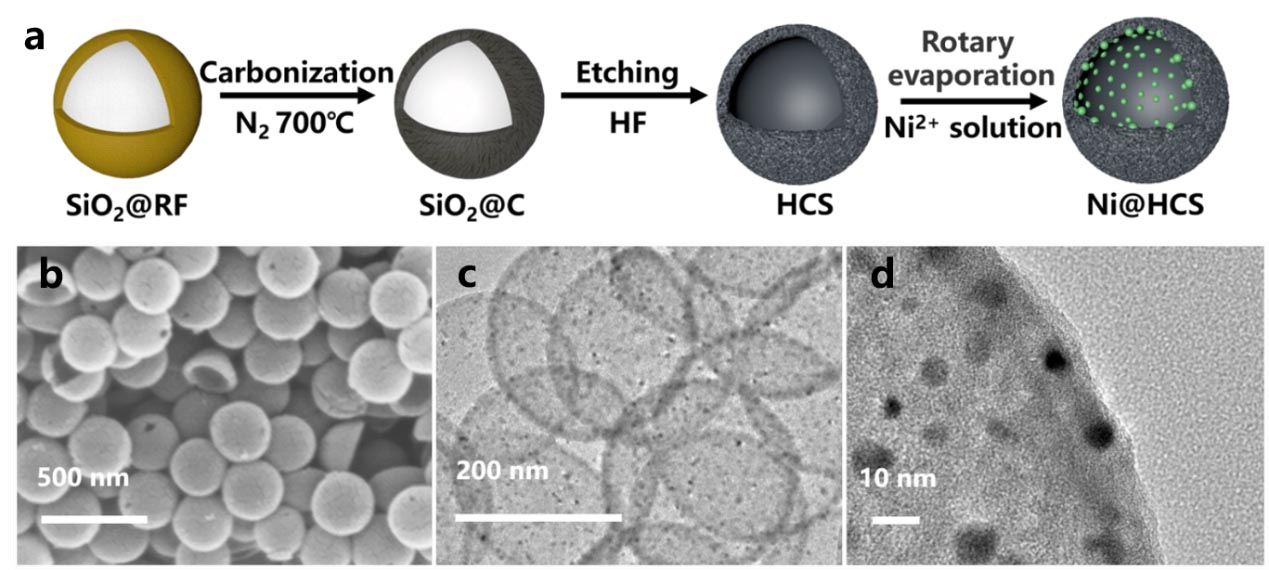

Recently, the team from the Institute of Solid State Physics, Hefei Institutes of Physical Science (HFIPS), Chinese Academy of Sciences (CAS) obtained a catalyst composed of the hollow carbon sphere and inner Ni nanoparticles (Ni@HCS), which displayed good performance when applied in the aqueous phase hydrogenation rearrangement tandem reaction of furfural (FAL), a typical aqueous phase reaction.

They found that it can afford 100 % FAL conversion and 99% cyclopentanone (CPO) selectivity at a mild condition (150 °C, 2 MPa H2, 4h).

In heterogeneous catalysis, the deactivation of catalysts caused by active metal loss, agglomeration, and sintering has always been the crux of limiting the development of supported metal catalysts, especially in the aqueous phase under high temperature. In addition, improving the selectivity of the target product in the reaction is also a big challenge in the preparation of catalysts.

Thanks to the shape-selective catalysis induced by the void-confinement effect of the hollow structure, the Ni@HCS has improved selectivity toward target product compared with active carbon supported catalysts.

More importantly, this hollow structure catalyst showed much better stability compared with active carbon supported catalysts as it can maintain its activity after 10 cycle experiments. According to CHEN Chun, member of the team, it's because the protective effect of hollow carbon spheres on active metals greatly reduced the loss of metals in the reaction process.

Scientists conducted more experiment to explained the phenomena. ICP-AES results show that the Ni content of Ni@HCS has a tiny change after the reaction while the active carbon supported catalysts show over 60% metal loss during the reaction. In addition, the synthetic method is also applicable to other metal catalysts and other reactions.

The corresponding research has been published in Applied Catalysis B: Environmental.

This work was supported by the National Natural Science Foundation of China.

Figure 1. (a) synthesis process of the catalyst; (b) SEM image of Ni@HCS; (c, d) TEM images of Ni@HCS. (Image by HU Zhi)

Figure 2. (a) cycle performance of Ni@HCS; (b) cycle performance of Ni catalyst using active carbon as support. (Image by HU Zhi)